-

THE BULK WEIGHT OF GRINDING BALLS

· The act introduces the average value of bulk weight by 3 weighing results. The obtained result of bulk weight determination can be used in operational accounting, control of grinding process. In our next articles we will consider the methodology for determining the bulk weight of grinding media in a working ball mill.

Get Price -

Grinding Media Wear Rate Calculation in Ball Mill

· The average weight of the balls of diameter between Da and Db is equal to the total weight of the balls divided by the total number of balls, or. By use of formula (31) it is possible to compute the actual screen analysis of the balls in the mill. If the balls are removed from the mill when they reach a certain minimum diameter, D0, formula (31) becomes, % W't = Da³ – Db³/Dm³ – Do³ ...

Get Price -

Ball screw

Ball screw are classified using "accuracy grades" from C0 (most precise) to C10. Ball return systems. The circulating balls travel inside the thread form of the screw and nut, and balls are recirculated through various types of return mechanisms. If the ball nut did not have a return mechanism the balls would fall out of the end of the ball nut ...

Get Price -

Physics of Wind Turbines | Energy Fundamentals

The optimal tip speed ratio is about one for the Western mill, barely over 2 for the fourbladed type, and 7−8 for the threebladed rotors. At their optimal tip speed ratio, threebladed rotors achieve a c p value of 48% and come closer to the ideal value of 59% than wind turbines with 4 blades. For wind turbines with two blades or weightbalanced onebladed rotor configurations, the yield ...

Get Price -

Ball Mill Capacity Dimensions 2013

weight (w/o media) BM 16 16 322 46 43 15 21 18 42 52 43 x 780 BM 26 26 16 530 42 39 18 24 18 45 54 43 x 1,000 BM 42 42 25 10 842 39 36 21 28 21 51 54 54 x 1,200 BM 59 59 35 15 1,178 36 33 24 30 21 54 62 50 x 1,560 BM 71 71 42 18 1,414 36 33 24 36 21 54 69 50 x 1,630 ...

Get Price -

Introduction to rubber processing and safety issues

The floating weight and the lower edge of the front hopper door at the feed opening. The trap at the bottom of the weight is more dangerous. Operators are at risk when sweeping down or when adding lubricant or other small ingredients. Where access to the trap is possible, interlock movement of the . floating weight with the hopper door.

Get Price -

Breeding – ball pythons

Ball Python Breeding. Many people feel the next logical step in the world of keeping snakes is breeding them. It's up to the snake owner if they want to take this step, but it is truly a rewarding, exciting and amazing experience. Breeding Size. As with most snakes, the weight of a ball python is a bit more important than the age of the snake when determining if the snake is ready for ...

Get Price -

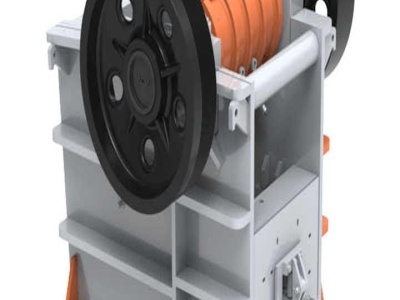

TF Lab 1 | A fine presentation of lab work

· A ball mill is a type of grinder which consists of a cylinder. It is used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. The cylinder rotates around a horizontal axis. It is partially filled with the grinding medium and the material to be ground. Materials which can be used as media are ceramic balls, pebbles and stainless steel balls. Large to medium ...

Get Price -

Tungsten carbide

Tungsten carbide (chemical formula: WC) is a chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes through a process called sintering for use in industrial machinery, cutting tools, abrasives, armorpiercing shells and jewellery.

Get Price -

Glass Weight Calculator | Glass Weight Estimator | Glass ...

The weight of any laminate interlayer is not considered in this estimation tool as its weight would be insignificant when compared to the weight of the glass itself. Select your glass configuration options below to estimate the weight of the final glass: Select glass configuration: Single Double Triple. Select glass type and thickness: Pane 1: Select glass shape: Square. Rectangle. Circle ...

Get Price -

Stainless Steel Finishes Explained

· As a result, this allows for thinner gauge cladding, a subsequent possible cost saving and overall weight reduction. The pattern can be applied on one side or on both sides to achieve the 2sided patterned stainless steels. These are the designations that fall into this group. 2F Finish. It usually starts with a 2B or 2R mill finish.

Get Price -

The grinding balls bulk weight in fully unloaded mill

· The grinding balls bulk weight determined by using tabular data. The grinding balls bulk weight corresponds to the calculated average grinding balls diameter in the mill. Calculated (tabular) data of the steel grinding balls bulk weight present in the tables of the following specialized printed publiions: Olevsky, Grinding equipment of ...

Get Price -

Lab Report 1 and 2

· Ball Mill is the equipment to be used for size reduction. It is a kind of grinder used for intermediate or fine grinding. Ball mill is a metal cylinder which rotates about its horizontal axis. The coarse sugar charged along with the metal balls breaks to fine powder by impact of metal balls. The size reduction is actually to make the too large to be used solid materials usable. It leads to an ...

Get Price -

MOISTURE CONTENT BY THE OVENDRY METHOD FOR .

mill measurement and, in fact, is as accurate as we ever try to get at the university. So, if the ovendry sample weight will always be more than 1000 g ( Ibs), the a scale that reads to 1 gram is very adequate. In general, we have found that a scale that reads to the nearest g is what a mill needs for small samples. The range or weighing capacity of the scale needs to be adequate to ...

Get Price -

Fitness Equipment and Smart Tech | Les Mills

The new SMARTBAR ™ and weight plate set has been reengineered for new levels of performance. Its cutting edge technology allows for faster, smoother weight plate transitions with no need for clips to hold weights in place. SHOP NOW . 56% of participants say the quality of equipment used for BODYPUMP™ has an influence on whether they choose to continue their membership. SMARTSTEP. Users ...

Get Price -

calculating ball weight in a ball mill

The correct determination of the grinding balls bulk weight in mill allows accurately determination the mill balls feed weight. More. How to Size a Ball Mill Design Calculator Formula A) Total Apparent Volumetric Charge Filling including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls expressed as a percentage of the net internal mill ...

Get Price -

Boilers

typically with an average particle size of about 25 µm ( in). Coal burns in suspension, like the combustion in an oil or gasfired boiler. Coal is pulverized in some type of large mill Pulverized coal is fired out into the furnace volume using burners that look somewhat like oil or gas burners. ME 416/516 BW Pyrites trap Windbox Classifier Raw coal feeder Driving mechanism Balls (~18 ...

Get Price -

Nanoparticle

A nanoparticle or ultrafine particle is usually defined as a particle of matter that is between 1 and 100 nanometres (nm) in diameter. The term is sometimes used for larger particles, up to 500 nm, [citation needed] or fibers and tubes that are less than 100 nm in only two directions. At the lowest range, metal particles smaller than 1 nm are usually called atom clusters instead.

Get Price -

Baltec

Ball Weight and Density How much will a ball of a given diameter in a certain material weigh? The answer is calculated by multiplying the volume of the ball by the density of the material. text"Weight" = text"Volume" ⋅ text"Density" For example, calculate the weight of a two inch diameter lead ball: text"Volume" = {4 ⋅ π ⋅ R^3 }/ 3 π, a universal constant = 4 ⋅ π ...

Get Price