-

Table : Principle Ores of some Important Metals aash ...

Ores which contains some magnetic particles or they can attract by the magnetic field only they can be concentrated by magnetic separation method. Among the ores mentioned in table, the ores of iron such as haematite, magnetite, siderite, and iron pyrites can be separated by the process of magnetic .

Get Price -

FPX Nickel Metallurgical Testing Demonstrates Significant ...

25/02/2019 · In summary, the production of a 55% to 72% nickel concentrate and an iron ore concentrate grading 58 to 64% Fe from the Baptiste composite sample with a feed grade of % DTR Ni is based on traditional grinding, magnetic separation and .

Get Price -

Nickel element extraction, mining technique – flash ...

The concentrate contains 612 percent nickel content. Magnetic separators can be used in floatation, since some nickelcontaining sulfides are magnetic. The concentrate of nickel obtained is then leached with either sulphuric acid or ammonia, dried and smelted similarly like copper.

Get Price -

Nickel Mines, Nickel Extraction Process, Nickel Recovery ...

[Introduction]: Nickel ore can be divided into copper sulfide nickel ore and nickel oxide is the main beneficiation method when processing copper sulfide nickel ore, and magnetic separating and gravity separating are the commonly auxiliary methods.

Get Price -

Nickel in British Columbia

Owned and operated by Hard Creek Nickel Corporation Estimated mine life of 27 years, average annual production of 75M pounds of nickel (2011 Preliminary Economic Assessment) Clean, highgrade nickel concentrate of 18% with less than 8% magnesium oxide Total ore .

Get Price -

Nickel Ores and Minerals

26/09/2016 · Nickel Ores and Minerals. To test the presence of nickel in a mineral, by means of the blowpipe, requires great care. If heated on charcoal, together with carbonate of soda in the inner flame, a grey metallic powder, attractable by the magnet, is formed. If heated with borax on platinum wire in the outer frame, a hyacinth red to violet brown ...

Get Price -

PAPER OPEN ACCESS 1HZPHWKRGVRISURFHVVLQJRI ...

22/12/2020 · It can be assumed that the combination of gravitationally magnetic concentration methods and reductive sulfuric acid leaching of nickel ore makes it possible to produce standard platinum concentrate from sinter. After magnetic separation of ore, the main part of magnetic fraction is iron and chrome. The most

Get Price -

Additives in Selective Reduction of Lateritic Nickel Ores ...

The sulfur content in the reductant also influenced the selective reduction process. It promotes more sulfidation of iron, thus increasing the nickel grade in concentrate. AB In this work, the selective reduction of lateritic nickel ore was carried out using sodium sulfate, sodium carbonate, and sodium chloride as additives.

Get Price -

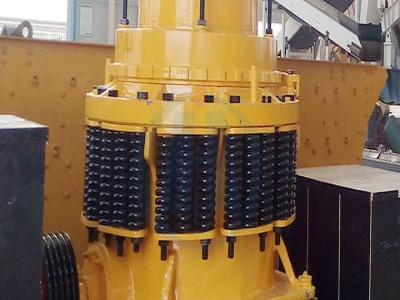

Nickel Ore Concentration Plant

Nickel Ore Concentration Plant. ... magnetic. Production Of Nickel Bioore From Hyperaccumulator Plant. ni in the b. coddii biomass was concentrated by a factor of about 17 to yield a residue containing % ni; this bioore ni content is substantially higher than the 1% to 2% ni typically found in mined ore. however, the b. coddii samples ...

Get Price -

AMIT 135: Lesson 1 Introduction – Mining Mill Operator ...

Magnetic Separation: Separates magnetic ore (pyrrhotite) from nonmagnetic ore (copper and nickel concentrates). Froth Flotation: Nonmagnetic ore is sent to a series of rougher and cleaner flotation cells to produce nickel concentrate. Drying: Thermal removal of liquid moisture . Calcining: Thermal decomposition of a material.

Get Price -

Chloridization and Reduction Roasting of HighMagnesium ...

The chloridization and reduction roasting of highmagnesium, lownickel oxide ore containing pct Ni and pct MgO were investigated in this study. Mineralogical investigation indied that pct of nickel was associated with silies, and nickel was well distributed in mineral in the form of isomorphism. A series of chloridization tests with different added proportions of sodium ...

Get Price -

Effect of sulfur content in reductants with variations of ...

10/08/2021 · Indonesia supply accounts for 16 % of the world's lateritic nickel ore, with the estimation reaching billion tons. The process of refining lateritic nickel ore can be considered as one of the main problems faced by the world mining industry, taking into account the economic and energy aspects.

Get Price -

The beneficiation process of nickel ore,coppernickel ...

24/09/2020 · Nickel ore is mainly divided into coppernickel sulfide ore and nickel oxide ore, and their beneficiation and processing methods are completely different. The main method for beneficiation of coppernickel sulfide ore is flotation, while magnetic separation and gravity separation are usually auxiliary beneficiation methods .

Get Price -

Recovery of Magnetite from Leached Lateriteresidue by ...

magnetic separator. The ore was treated through selective reduction followed by sulphuric acid leaching to recover nickel while iron remained in residual solid. The Vibrating Sample Magnetometer measured the magnetic properties of the ore, as a fundamental of magnetic separation. Magnetic separation was carried out using a Davis Tube Tester.

Get Price -

Nickel Ores

Nickel Ores. The principal ores of nickel are magnetic nickeliferous pyrites, nickel arsenides (especially kupfer nickel, and nickel arsenosulphide or grey nickel), and the hydrosilies of nickel and magnesia. The firstnamed ore is simply magnetic pyrites containing a certain proportion of nickel sulphide, and is one of the most important.

Get Price -

nickel ore processing magnetic separation

1/11/2020 The magnetic separation efficiency of nickel from the laterite ore was evaluated using the recovery ratio of nickel R ni using the formula: (1) R Ni = m Ni × β Ni M Ni × γ Ni × 100 % where m Ni is the mass of the magnetic product, g; β Ni is the nickel content inM. Read More++.

Get Price -

About nickel | Nickel Institute

About nickel. Nickel is a naturallyoccurring metallic element with a silverywhite, shiny appearance. It is the fifthmost common element on earth and occurs extensively in the earth's crust and core. Nickel, along with iron, is also a common element in meteorites and can even be found in small quantities in plants, animals and seawater.

Get Price -

NICKEL RECOVERY FROM ELECTRIC ARC FURNACE SLAG BY MAGNETIC .

possible to obtain a magnetic product with nickel grade close to that of the primary raw material or even better, with ... metallurgical processing of nickel laterite ores is run by GMM SA LARCO. In 2011, the ... increased concentration because of the inefficient separation of metal phase from slag. Hence, they are actually considered as a

Get Price -

Case No COMP/ INCO/FALCONBRIDG E

Processing of nickel ores (16) Typically, nickel ores are first milled and concentrated to obtain nickel concentrate. The ore is first ground into a fine powder (milling), which may then be concentrated by magnetic separation and flotation, in which nickelbearing material is separated by liquid surfactants. Sulphide ores are generally amenable ...

Get Price -

Nickel for the 21April 2021 Century

8 Baptiste Deposit (2020 PEA) • 32,000 metres drilled • LOM average head grade % DTR Ni1,3 Sid Target • 2 holes drilled, 320m apart • 282m of % Ni in alloy2 • 163m of % Ni in alloy2 • Open along strike and at depth B Target • 1 hole drilled, km from Sid, 263m of % DTR Ni1 • Open along strike and at depth Van Target • Drillready target

Get Price