-

What exactly is Mill Scale and what is done about it

In a rolling mill where the steel will be stretched and squished the mill scale will first be removed mostly by water jets, or by sand blasting in some shops or by vibrating rolls in others and the mill scale will fall into a pit below the equipment where it will also be joined by rolling mill lubricants and bearing oils and water.

Get Price -

Metal Rolling and Shaping

Jun 17, 2019 · Good quality products have their surfaces covered in mill scale, an oxide that forms at high temperatures. Mill scale is usually removed via pickling or smooth clean surface (SCS) process, revealing a smooth surface. Hot rolling has a higher carbon tolerance for included carbon, and is therefore more difficult for a blacksmith to use.

Get Price -

Water treatment and cooling plant for Wire Rod and Rebar ...

Scale Pit Settling Deoling ... Water treatment and cooling plant for Wire Bar Rolling mill. Iran Water treatment and cooling plant for Bar Rolling mill for Union Iron Steel. Abu Dhabi SIDERIDRAULIC System spa Via Badia 15 25060 Cellatica (BS) Phone +39 Fax +39 EMail info SIDERIDRAULIC ...

Get Price -

97 N Scale Steel Mill Modeling ideas | steel mill, n scale ...

Oct 27, 2020 steel mill layout. See more ideas about steel mill, n scale, layout.

Get Price -

Walthers

Rolling mills are loed at many steel mill complexes, but they can also be used as standalone facilities. The Ashland Iron and Steel Rolling Mill is also similar to buildings used for vehicle and railcar assembly, metal smelting and fabriion, refractories and more, so this versatile structure will have a home on any layout.

Get Price -

Projects

New Slitting Line Foundations and Scale Pit Depth 21,00 m. Water Pipes Tunnel – Tundish Heating Line – New Forging Furnaces – New Peeling and Testing Line ... Structural refurbishment of water tunnel. Rolling Mill Wire Rod Mill Meer Drive Installation. ... Steel Melt Shop and Rolling Mill. New Wire Rod Mill. New Wire Rod Mill.

Get Price -

Steel Making | Kubes Alloys Wear Plates

Water Flushed Slag Chutes; ROLLING. Primary Water Scarfer Flume; Conditioner (Grinder) Target Plate; Hot Mill Downcomer Side Guides; Cold Mill/Galvanized Uncoiler Side Guides; Tin Temper Upender (Horiz. To Vertical Coil) Crop Shear Scale Pit Drag Cleanouts; Hot Mill Side Guides Aprons (1st Two Mills) Scrap Chopper Inlets Scrap; Baller ...

Get Price -

(PDF) Sustainable Water Recovery from Cold Roll Mill of ...

Water management plays a vital role in steel industry. The present work is carried out in cold rolling mill aiming to recovery maximum water. In CRM process the acid waste, alkaline waste and oil and grease wastewater generated. This wastewater is

Get Price -

Rolling Process: Working, Appliion, Defects, Type of ...

5. Cluster Rolling Mills: In this type of rolling mill, there are two basic roles that are backed up by two or more rolls which are bigger than those two basic rolls. These backed up rolls give more pressure to the basic rolls to heavily press the strip.

Get Price -

Heavy Duty Submersible Pumps: Forge Solution to Scale ...

Mar 01, 2007 · Pit Stop − This pit presents an important link in how process effluent recycles through the minimill. The hot wastewater carries slag sprayed off the redhot billets of new steel. Powerful ITT Flygt Model 5550 submersible pumps fit with agitators keep the slag churned in suspension as the effluent is pumped downline to a cooling pond and ...

Get Price -

My N scale Steel Mills final trackplan | Zealot

Nov 27, 2007 · My N scale Steel Mills final trackplan. Rancho Santa Margarita, Cali. Hi guys, I was talking to my grandpa about starting my steel mill finally. You might member this plan that I did a while back for a smaller layout that was going to go under my HO layout. well I was talking about it and my grandpa wanted to help me build the layout.

Get Price -

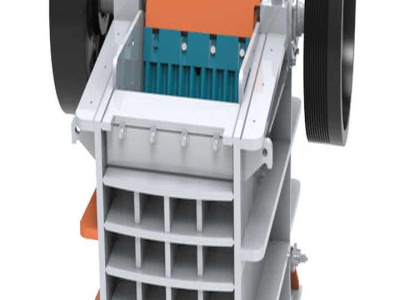

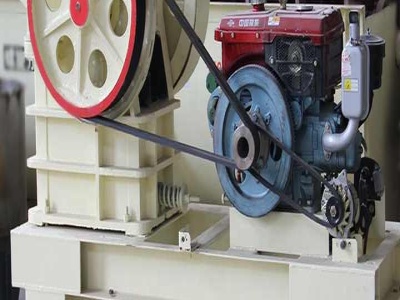

Rolling Mill Machine | Steel Rolling Mill | Used Rolling ...

Hot rolling mills roll the steel at temperatures over 1700° F which is above the steels recrystallization temperature meaning that it can be shaped and formed more easily and the steel can be rolled in much larger sizes. Hot rolled steel products will shrink slightly after they cool and are therefore harder to .

Get Price -

Water treatment plant for a rollingmill train.

Jan 01, 2009 · If we consider that the maximum capacity of the rollingmill train is 90 Tonnes/hour, and we estimate a formation of scale equal to % of the production total, the maximum amount of scale that the contact water will remove is 18 Kg/hour, with a density of g/cm3.

Get Price -

Environmental Solutions: Systems Optimization Schedule

This twoday program provides a detailed overview of optimizing the resourceconsuming processes and the environmental control systems that are typically found in steel mills. These include dust and fume capture systems, process scrubbers, cooling towers, air and water distribution systems, byproduct recovery processes, and wastewater treatment ...

Get Price -

Water Treatment in the Steel Industry | Fluence

May 17, 2019 · Steel Production Cycle. Steel is produced from raw materials in an integrated cycle, or with scrap melted in an electric arc furnace (EAF). Average water intake for integrated plants is m 3 per metric ton of steel, with average discharges at m 3 /t. For EAF plants, the average intake is m 3 /t, with mean discharge at m 3 /t.

Get Price -

Ovako first in the world to heat steel using hydrogen

Apr 28, 2020 · Ovako first in the world to heat steel using hydrogen. Scandinavian steelmaker Ovako and Linde Gas AB have conducted a fullscale trial using hydrogen to heat steel before rolling. The steelmaker claims that the trial was performed with good results in one of the company's pit furnaces at the Hofors rolling mill in Sweden.

Get Price -

water scale pit steel rolling mill

Water (scale) pit in steel rolling mill? | Yahoo Answers · Best Answer: HSM only, 2 pits, first pit, the scale pit, collects the water from the reheat furnace(s) to the Roughing mill to coilbox to the end of the Finishing mills, but not the Run out tables. second pit collects water from the start of .

Get Price