-

Energy Use of Fine Grinding in Mineral Processing

25/04/2013 · Intermediate ball mill 40 to 400 impact+attrition tower mill 40 to 400 attrition Fine stirred mills <30 attrition ... A Vertimill has been used to grind to sizes below 10 lm.[11] ... fine grinding in ball mills. These are 5 to 12mm spherical or oblong cast steel pellets, charged into ball ...

Get Price -

VertiMill® – Preparing the feed within floatable regime at ...

It was observed that the effect of grinding time and ball to material ratio had significant impact on product fineness as well as on specific comminution energy. The effect of individual ...

Get Price -

TECHNOLOGY SELECTION OF STIRRED MILLS FOR ENERGY ...

Figure 4Typical Vertimill™ circuit in a reverse closed circuit mode The VTM™ is fed from the top. As the feed enters the grinding chamber, the downward movement of the feed material into the grinding zone is influenced by the upward velocity created by the recycle pump. The combination of this uprising velocity and the mill's vertical

Get Price -

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator ...

Vertimill ® (Metso Minerals) Wet grinding only; Top or bottom feed; Grinding by attrition/abrasion; Primary or regrinding mill; Ideal for "precision" grinding on finer products; Restriction in feed size (6mm) Restriction in energy (1119 kW/ 15oo hp) Ball size max. 30mm; Vertimill by .

Get Price -

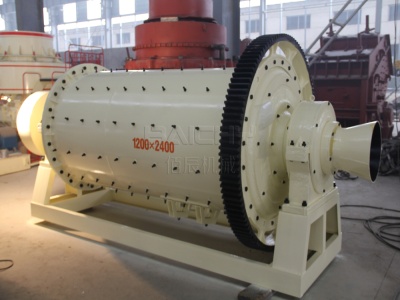

Wet Grid Ball Mill

The main function of the steel ball in the ball mill is to impact crush the material and also play a certain grinding effect. Therefore, the purpose of grading steel balls is to meet the requirements of these two aspects. The quality of the crushing effect directly affects the grinding efficiency, and ultimately affects the output of the ball mill.

Get Price -

Vertical mill

In fact, in the same appliion a Vertimill® has 50% less footprint than a ball mill. Lower operating cost Vertimill® is an energy efficient grinding machine. They tend to grind more efficiently than for example ball mills with feeds as coarse as 6 mm to products finer than 20 microns. This provides up to a 40% higher energy efficiency.

Get Price -

Development and Implementation of the new 2240 kW (3000 .

Vertimill in Secondary Grinding • Semi Parallel with ball mill because cyclone under flow is split 7 ways • Vertimill stream is pre screen at screen with 6 mm apertures: Oversize ~(10%) sent to ball mill, under size (~90%) sent to Vertimill • Grinding duty – F80 –600 µm .

Get Price -

industrial mills vertimills

Find out all of the information about the Corporation product: vertical mill / ball / with rods / for ore Vertimill® for fine wet grinding. Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale.

Get Price -

ball mill noise control methods vertimill dry grinding ...

Ball mill level control Henan Mining Machinery Co., Ltd. Autogenous and SemiAutogenous Mills The optimum solution for wet grinding or an immediate size for further grinding in a ball mill pebble mill VERTIMILL or a stirred media detritor SMD A second level of testing using a 1000 pound sample conducted . services Development of a method to ...

Get Price -

Vertimill Grinding Ball Effect

Vertimill Grinding Ball Effect Grinding in Ball Mills Modeling and Process Control Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical mechanical and chemical characteristics...As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying ...

Get Price -

Vertimill Grinding Ball Effect

vertimill grinding ball effect in bahamas; vertimill grinding ball effect in bahamas. Vertimill is an energy efficient grinding machine They tend to grind more efficiently than for example ball mills with feeds as coarse as 6 mm to products finer than 20 microns This provides up to a 40 higher energy efficiency With the Vertimill simple and. ball size effect on final product size in grinding ...

Get Price -

Vertimill Grinding Ball

Vertimill Grinding Ball. Grinding in a vertical mill vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes paints pyrotechnics cements and ceramicst is an energy efficient alternative for a ball. Get a Quote . Vertimill. Vertimill is an energy efficient grinding machine they tend to grind more efficiently than for ...

Get Price -

vertical ball milling on laboratoiry

Vertimill VS Ball Mill Grinding Classifiion. I think the original question does not refer to wet or dry milling, so we have wet vertical ball mills and wet horizontal ball mills and dry vertical ball mills and dry horizontal ball mills. Even Balls is a general term,cylpeps,steel balls,beads etc. are used in ball .

Get Price -

Grinding / MCES – Metso official distributor

Mechanically, the Vertimill is a very simple machine with an agitating screw suspended into the grinding chamber, supported by spherical roller bearings and driven by a fixed speed motor through a planetary gearbox. • Ball Mils. Metso overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30' x 41' and as much as 30,000 HP. A ...

Get Price -

100 HP Metso VTM150LS Vertimill

Vertimill® is typically arranged in closed circuit and fed by the cyclone underflow. The motor power turns the Vertimill® screw at constant speed to stir the grinding balls and slurry. As the particles are ground, they rise to the top of the mill and overflow into the separating tank.

Get Price -

Assessing Vertimill Ultrafine Grinding Performance: The ...

· This resulted in approximately 25% spare regrind capacity in the Concentrator #2 design, complete spare parts interchangeability and potential future expansion capacity to 50,000 t/d with no circuit this context, a study was initiated to assess not only the performance of a Vertimill grinding circuit processing a copper concentrate to a particle size of 80% passing 17 µm but also ...

Get Price -

Vertimill Ball Port Manufacturer

Vertimill Ball Port Manufacturer. Vertimill Ball Port Manufacturer Ball Mill Vertimill SMD 100000 10000 1000 Microns 100 10 1 Mill Ty pe Typical Grinding Ranges Ball Mills and stirred mills are applied across a wide range of appliions but for each ore there is optimum efficient range The figure to the left shows the typical appliion ranges for ball mills and stirred mill The Vertimill is ...

Get Price -

Tertiary grinding mills for NSW gold mine

Tertiary grinding mills for NSW gold mine. The first 3000 HP (2240 kW) Vertimill, known as the VTM3000WB, is destined for Newcrest Mining Ltd.'s Cadia Valley Operations, where it will be ...

Get Price -

Vertimill Grinding Ball Effect

Vertimill grinding ball effect (mill grinding) equipment Of the entire Vertimill population . VERTIMILL Grinding Mills 2011 Scribd Aug 6, Stirred milling machine development and appliion VS Ball Mill Grinding Classifiion One comment that I did not see here is the potential for differential grinding, especially in vertical mills, but also in ball mills. That is ...

Get Price -

Vertimill Archives

Metso Outotec will deliver identical grinding lines to both sites, consisting of stateoftheart Premier™ ball mills (one pictured) and energyefficient Vertimill® VTM3000 stirred mills, each line featuring a capacity of 400 t/h. The deliveries are expected to take place in January 2022.

Get Price -

Ball Mill Power Selection For Mining

Vertimill® has an excellent turndown ratio and can be operated at lower than installed power with less effect on grind efficiency than for example horizontal ball mills Feed FlowRate This parameter is used in conjunction with the feed density and motor power to establish the grinding rate in kWh/mt.

Get Price -

Scale up and simulation of Vertimill™ pilot test operated ...

01/01/2014 · Vertimill™ has been used in regrind circuits during the past years due to its greater efficiency when compared to the conventional tube ball paper presents the Vertimill™ pilot grinding tests with a sample of copper ore carried out in closed circuit with a high frequency sample was crushed 100% to <6 operating variables were measured under controlled .

Get Price -

GRINDING CIRCUIT OPTIMISATION

grinding rather than the conventional ball mill. The implementation of this new circuit design was based on Cannington's positive experience with Vertimill® technology as well as results from modelling and simulation studies. A number of complete grinding circuit surveys were carried out in order to assess the performance of the existing circuit and to evaluate circuit expansion and ...

Get Price -

Vertimill VS Ball Mill

Vertimill VS Ball Mill (14 replies) Paul Morrow. 6 years ago. ... Fine material by impact grinding/aracting ... To get energy efficient grinding below approx. 40 µm you need to have finer grinding balls than are suitable for the tumbling mill. So, the case for the stirred media mill that often has media in the range 510 mm if used as a ...

Get Price