-

Ball Mill|Ball Miller Metals

Ball Mills Mt Baker Mining and Metals. Ball mills have been the primary piece of machinery in traditional hard rock circuits for 100+ years. They are proven workhorses, with discharge mesh sizes from ~40M to <200M. Use of a ball mill is the best choice when long term, stationary milling can be justified by an operation. get price

Get Price -

Joe Tsoi

Aug 2013 Dec 20152 years 5 months. Vancouver, British Columbia. Worked closely with EPCs and end users to provide optimized process solutions in mineral processing and bulk materials handling. Networked with industry professionals to obtain market intel and generate opportunities. Developed sales strategies with global team to ensure an ...

Get Price -

Electrowinning Equipment

Jul 02, 2012 · Today's market for metals is very cyclical. When prices go up, mines want to start up or expand more quickly than orders for new ball mills can be fulfilled. Hence, there is a robust market for used ball mills, with many vendors competing for used ball mills from shuttered facilities.

Get Price -

Geometallurgy case studies – bridging disciplines (Part 2 ...

Case Study 2: Openpit gold – comminution parameters. The operation encompasses multiple related epithermal gold deposits and a conventional carboninleach processing plant. Comminution is achieved using a single stage of crushing, followed by a SAG mill / ball mill / pebble crusher arrangement to generate leach feed with P80 of 150 µm.

Get Price -

Eriez

Rod Ball Mills. The Ball/Rod mills are meant for producing fine particle size reduction through attrition and compressive forces at the grain size level. They are the most effective laboratory mills for batchwise, rapid grinding of mediumhard to very hard samples down to finest particle sizes.

Get Price -

Keeping an eye out for grinding mill dropped charge and ...

Aug 12, 2020 · To help the grinding process, water and steel balls are added to the process which then form the charge in the mill. Ball mill charge contains a significant amount of steel balls and can become ...

Get Price -

Ball Mills

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary ...

Get Price -

Easy Ways to Extract Gold from a Rock (with Pictures ...

Nov 22, 2020 · Use a metal rod with the metal container to create a makeshift mortar and pestle that are strong enough to use with rocks. Press the end of the metal rod into the rock pebbles, then drag the rod along the bottom and sides of the metal container. Grind the rocks until the pieces are slightly larger than the holes in the bottom of your mining pan.

Get Price -

Milling Drying Limestone Powders

Grinding Mill Machine Mineral Mill Limestone Grinding. Which milling process is used is the key to the success of the desulfurization project. Among many milling processes LM series vertical mills MTW series European version mills and TGM series overpressure trapezoidal milling limestone mills are recommended for the desulfurization milling process in power plant steel plants.

Get Price -

Ball Mill

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary ...

Get Price -

copper extraction bbc bitesize

· Obtaining metals from metal oxides BBC Bitesize. To extract copper, you mix copper oxide powder with carbon powder. You then heat the mixture strongly for a few minutes in a crucible. It is important to keep a lid on the crucible, otherwise the...

Get Price -

commonly used separation techniques in mineral processing

Jan 29, 2021 · The most common and notable example of this are precious metal values (gold, silver etc.) where the beneficiation process is applied directly on runofmine ores followed by the extraction of gold and in some cases silver as a relatively pure metal within the mineral processing circuit. Processing Approach and Method . Chat

Get Price -

Using Ball Mills to Extract Raw Gold from Ores ...

Jun 14, 2018 · Hence, a mill is a piece of equipment used to grind ores. Its major purpose is to perform the grinding and blending of rocks and ores to release any freegold that is contained within them. At major mines, the mill was the critical equipment that was required to process the ores that were extracted from deep underground.

Get Price -

mills for metals

ball mill for obtain metals from rocks Bussa Machinery Ball Mill For Reference Price: Get Latest Price Ball mill is the vital equipment for recrushing after being crushed Processing ability: 05500t/h Feeding size: ≤25mm Applied material: cement, silie, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal

Get Price -

Meteorite Identifiion

The largest group of space rocks is the chondrite type of stone meteorite, and they contain nickeliron metal in the form of tiny grains stered throughout the matrix of the rock. There are manmade rocklike materials such as slags that may have bits of metal, but they will not have a solid rock .

Get Price -

Mill (grinding)

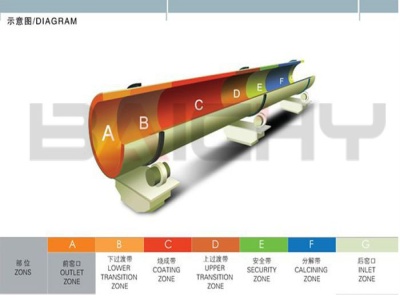

Ball mill. A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls. Ball mills normally operate with an approximate ball charge of 30%.

Get Price -

Article: Prediction of rock properties using grinding ...

Dec 16, 2020 · Laboratory experiments conducted on samples of granite, limestone, slate and BHQ varying different parameters like quantity of feed, charge ratio, size of balls, grinding time, etc., at constant RPM of ball mill. Grinding characteristic curves used to obtain 25%, 50%, 80% cumulative passing sieve sizes.

Get Price -

Hard Rock Mining Tour: How a Mill Works

Hard Rock Mining Tour. Receiving Room Ore was received at the top of the mill building. Crushing The raw ore went through several crushers. The jaw crusher broke the rock into smaller pieces, and then the gyratory crusher turned the pieces into sandsized particles. Grinding A hopper introduced the crushed material to a rod or ball mill ...

Get Price -

Ball Mills

Explore Ball Mills for sale Australia wide on Australia's No1 online machinery classified. All Ball Mills posted here are either used Ball Mills or new Ball Mills. Browse more, so you can find Ball Mills that satisfy your needs!

Get Price -

What Is The Difference Between Ball Mill And High Pressure ...

Mill (grinding) Wikipedia, the free encyclopedia. The high pressure grinding rolls, often referred to as HPGRs ... The special feeding of bulk material through a hopper leads to a material bed between the two rollers. ... but purpose, construction and operation mode are different. ... Compared to ball mills HPGRs are achieving a 30 to...

Get Price