-

Sandvik Cone Crushers

Stationary cone crushers On January 1 Sandvik Mining and Rock Solutions Division Crushing and Screening became a business area of its own within Sandvik Group. We are called Sandvik Rock Processing Solutions and you'll find all our products within Stationary Crushing and Screening, Mobile Crushing and Screening and Attachment Tools (Breakers) on our new web site, .

Get Price -

Dust Collectors for Mining

Camfil 's Farr Gold Series® Dust Collectors offer an effective, efficient, and reliable solution for dust control in mining operations. They protect workers, the environment, and .

Get Price -

calculator design cone crusher

Cone Crusher Design Calculation PANOLA MiningCone Crusher Design Calculation 511 cone crushers cone crushers are commonly used for secondary tertiary and quaternary crushing duties two variations are available standard and short head the chief difference between cone and gyratory or jaw crushers crusher design calculation pdfcone crusher design calculation pdf Cone crushers .

Get Price -

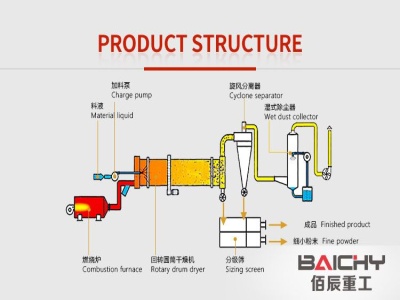

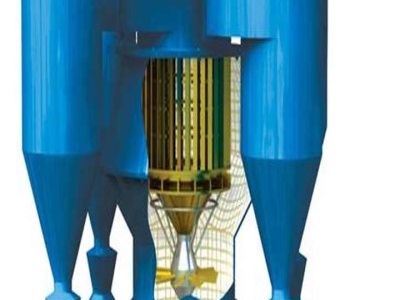

(PDF) Design and fabriion of cyclone separator

Project: Design And Fabriion Of 2D2D ... The cleaned gas leaves through the exit pipe at the top. ... It has a body diameter of 7cm with both lengths of the body and cone of 14 cm. The design ...

Get Price -

Ekati Diamond Mine, NorthWest Territories, Canada ...

In the process plant, a gyratory primary crusher reduces the ore to 300mm, coarse ore being stockpiled in a 20,000t storage building. A hot waterflushed cone crusher reduces the ore to 75mm before a highpressure roll crusher reduces it to minus 25mm.

Get Price -

Rio Tinto Brockman 4 Iron Ore Mine, Pilbara

· The Brockman 4 mine is designed to produce 22mtpa, with an operational lifespan of 20 years. A total of was apportioned by Rio Tinto in December 2010 to expand Brockman 4 and develop Western Turner Syncline iron ore project. The expansion will increase the production capacity of Rio Tinto in Pilbara region from 220mtpa to 283mtpa by 2013.

Get Price -

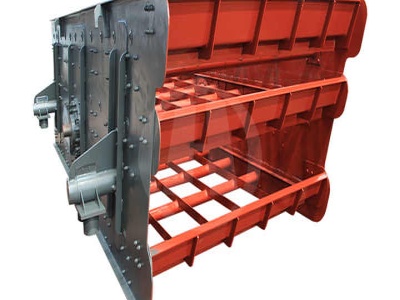

(PDF) Design of Impact stone crusher machine

Design of impact stone crus her machine. T esfaye O. T erefe, Getaw A. Tefera. Abstract: Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other ...

Get Price -

Quarrying Aggregates

The project described in this article selects safe and environmentally friendly crushing, shaping, screening and control processes to produce highquality sand and gravel aggregates, construction base materials and readymixed mortar, with an effective output of 600t/h and an average annual output of million tons.

Get Price -

cone crusher design 2 the best

Lanvin Crushing Circuit Tradeoff Study Lydian ... Table 42 Crushing and Screening Plant Design Basis – Key Parameters . ... screens, two secondary MP800st (or equivalent) cone crushers, three tertiary double ... nominal top lump size of 700 mm diameter to a top size of 355 mm and P80 of.

Get Price -

Project Management for Construction: The Design and ...

The second refers to the design capabilities that are available to the designers, ... Topdown design. ... A careful and thorough analysis of different conditions imposed by the construction project design and by site characteristics are taken into consideration to determine the best estimate.

Get Price -

Cone crusher basics in 4 minutes — SRP

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing.

Get Price -

Automatic s |

· The unit can crush 250 aluminum cans in just over 2 minutes, which is impressive. The crusher is made from metal and has got a basket on the top that can store up to 500 empty cans, compering other automatic s with can baskets that will hold maybe 10 cans, this unit is a beast. The hydraulic ram gets powered by a hydraulic power unit ...

Get Price -

Project Crashing in Project Management: Definition Best ...

· Project crashing is not just adding resources to get done faster, but it's getting the most in return for that extra expense. 5. Create a Budget. Like any project, once you've decided on your plan, you have to pay for it. Making a project crashing budget is the next step in executing your project crashing .

Get Price -

Industrial Cannabis Grinder | Custom Cones USA

The hightorque and low RPM design helps to preserve terpenes and trichomes in the flower material by reducing the amount of heat and stress applied to the the flower material. The blades of our grinder move much slower compared to a highrpm grinder like a blender or one of the weedwhacker style grinders with the plastic whips but still has enough torque to grind dense buds with ease.

Get Price -

Workshop Projects

First Prize 44 Personalized Dog Crate Name Tag by Itsatrav in Pets. 3 175. Partially Crunched and Uncrunched Cat Crunchy Sorter by alanamon in Pets. 3 253. 3D Printed Dog Puzzle Using Tinkercad by JPGrox in 3D Printing. Second Prize 1 37 Folding Metal Pegboard Tool Wall by SouthernStyleDIY in Organizing.

Get Price -

Jaw Crusher vs Cone Crusher: A Comparison

Cone crushers take care of secondary and tertiary crushing appliions. Fine and mediumsized aggregates (used in asphalt and concrete, for example) are created by an eccentrically rotating shaft that grinds the rocks between a robust metal cone and a fixed wall. The Blackhawk 100 Cone Crusher is an example of a powerful cone crushing machine.

Get Price -

Cone Crusher Plant Design

JXSC GP cone crusher is often used as the secondary and tertiary crusher in stone crusher plant. It can be an excellent replacement for a gyratory crusher. The brilliant design makes it with high power level and crushing capability, and stable performance through optimized wear parts.

Get Price -

DIVISION OVERVIEW

Flow controlled feed plates and chamber designs. Powercontrolled tertiary cone crusher liners. Fully corrugated primary crusher mantles. High tonnage / decreased power draw gyratory liner sets. Selfhardening jaw crusher tooth designs. Extended chamber gyratory and jaw crusher designs. GRADES AND OPTIONS

Get Price -

Home

Dynamic Equipment offers over 50 years of combined experience in plant design and an understanding of material flow. Whether you're starting a new operation or adding to an existing plant, Dynamic Equipment is ready and willing to apply our "knowhow" to get you up and running in .

Get Price