-

How to Treat Wastewater from Cement Ceramic Industry ...

1. Cooling Water: The major water use at most cement plants is for cooling. Cooling water is used for bearings on the kiln and grinding equipment, air compressors, burner pipes and finished cement. Most cooling is noncontact. Cooling use is approximately the same for both the wet and dry processes. 2.

Get Price -

Wet cement | Article about Wet cement by The Free Dictionary

concrete, structural masonry material made by mixing broken stone or gravel with sand, cement cement, binding material used in construction and engineering, often called hydraulic cement, typically made by heating a mixture of limestone and clay until it almost fuses and then grinding it to a fine powder.

Get Price -

How Portland Cement is Made? Manufacturing Process of ...

Aug 31, 2009 · Portland cement can be made by following two different processes – a dry one and a wet one. Joseph Aspdin first made portland cement in his kitchen stove in England in the 19th century. Lime and silica make up approximately 85% of portland cement. The materials that are commonly used are limestone, shells, chalk, shale, clay, slate, silica sand, and iron ore.

Get Price -

What is the difference between the dry and wet processes ...

In dry process all the materials in powder form are ground separated in the absence of water and then mixed in the desired proportion and the resultant product is fed into kiln for burning. This process results less consumption of energy. And low ...

Get Price -

Portland Cement

May 22, 2013 · There 2 main process that can be used in manufacturing of Portland Cement that is i) wet process ii) dry process. Wet Process. Raw materials are homogenized by crushing, grinding and blending so that approximately 80% of the raw material pass a sieve. The mix will be turned into form of slurry by adding 30 – 40% of water. It is then ...

Get Price -

TAJ DHALAI+ :: Products

Portland Pozzolana Cement (PPC) is manufactured by blending pozzolanic materials, OPC clinker, and gypsum either grinding them together or separately. Today Portland Pozzolana Cement is widely in demand for industrial and residential buildings, roads, dams, and machine foundations.

Get Price -

Difference Between Wet And Dry Process Of Cement ...

Wet process. 1 Mixing of Raw materials in wash mill with 35 to 50% water. 2 Materials exiting the mill are called "slurry" and have flowability characteristics. 3 Size of the kiln needed for the manufacturing of cement is bigger. 4 Raw material can be mixed easily, so .

Get Price -

Chemical Composition of Portland Cement Example | .

Mar 10, 2019 · Low HeatLow heat hydrationMassive structures ( dam)V. Sulfate resistantHigh sulfate resistanceFoundations in high sulfate soilsManufacture of CementThere are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a ...

Get Price -

Hongbo TAN | Professor (Full) | Doctor of Philosophy ...

In this paper, RP was treated by wet grinding to prepare submicronRP (SRP), and then SRP was used as an accelerator in various cementitious systems, including Portland cement system (PC), PC ...

Get Price -

Manufacturing of portland cement

Jul 31, 2016 · Manufacturing of portland cement. 2. CEMENT: • A powdery substance made by calcining lime and clay, mixed with water to form mortar or mixed with sand, gravel, and water to make concrete. • The raw materials required for manufacture of portland cement are calcareous materials,such as lime stone and chalk and argillaceous material,such as ...

Get Price -

14 different types of cement you must know | CivilRead

Feb 27, 2018 · This type of cement is manufactured by grinding ordinary Portland cement clinker with water oleic acid or stearic acid. These acids forms as a water repellent film around the cement particle which increases the shelf life of cement. The formed around each grain of cement reduces the rate of deterioration of the cement during long storage ...

Get Price -

Preparation for microlithium slag via wet grinding and ...

Request PDF | Preparation for microlithium slag via wet grinding and its appliion as accelerator in Portland cement | Industrial wastes consumed by the preparation of building materials is a ...

Get Price -

Our Portfolio – JK Lakshmi Cement

Portland Slag Cement (PSC) Ground Granulated Blast Furnace Slag (GGBS) is a byproduct from the blast furnaces used to make iron or steel. JK Lakshmi Cement produces high quality Portland Slag Cement by grinding the slag with the clinker.

Get Price -

FAQ | Central Plains CementCentral Plains Cement

Portland cement is a manufactured product made in several steps. First we carefully blend limestone with shale or clay and iron to a desired chemical composition. We then grind it to a fine powder called raw meal. We feed the raw meal to a rotary kiln that is fired .

Get Price -

Top Ten Portland Cement Uses

Composed of concrete, mortar, stucco and grout, it is produced as a fine powder by grinding the Portland cement clinker with calcium sulfate. The origins of the cement can be traced back to in the initial years of the 19th century. Portland cement has today found its way as being the basic ingredient for readymix concrete.

Get Price -

Explain dry and wet process of cement manufacturing

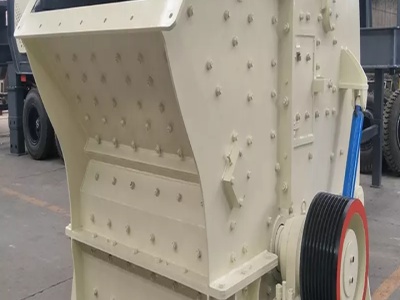

Dec 13, 2018 · The flowsheet diagram of the wet process for manufacturing Portland cement is given in Figure The limestone is disintegrated in crushers. The crushed limestone is fed to a tube mill, where the limestone and the clay, introduced as a slurry from a clay mixer, are simultaneously subjected to fine grinding.

Get Price -

Which cement manufacturing method is best, wet or dry? Why ...

If we consider the Quality and Rate then wet process is better and if we consider Fuel consumption and Time of Process then dry process is better. * Dry Process The both calcareous and argillaceous raw materials are firstly crushed in the gyratory...

Get Price -

R.

R. Emission limitations and restrictions for Portland cement kilns. Rule 817. (1) As used in this rule: (a) "Clinker" means the product of a Portland cement kiln from which finished cement is manufactured by milling and grinding. (b) "Long dry kiln" means a Portland cement kiln that employs no preheating of the feed.

Get Price -

Cement Constituent | CivilSirJi

Jun 28, 2021 · Then its harden like as a stone found In mines in Portland city that's why cement called as Portland cement. 1) Manufacturing of cement. 2) Hydration if cement. 3) Type of cement. 4) Testing of cement. Basically cement is fine material which is having both Cohesive Adhesive property which is binding ability of same material different material

Get Price -

Portland Cement Background Information For Proposed ...

Approximately xlO9 Joules ( xlO6 Btu's) are required to manufacture 1 Mg (1 ton) of clinker in a wet process portland cement plant. In a dry process plant, only xlO9 Joules (4 xlO6 Btu's) are needed. The added coal required in wet process kilns increases the S02 emission potential.

Get Price -

Manufacture Of Portland Cement Wet Process And Dry Process

This grinding is done wet or dry, depending on the process . Portland cement and process of Manufacturing Civil . Portland cement and process of Manufacturing The dry process of portland cement The wet process for the manufacturing of Portland cement. In the wet process, limestone is first crushed to smaller fragments.

Get Price -

Dry process of cement – we civil engineers

Aug 24, 2018 · Dry process. These are two different processes of manufacturing cement. wet process minerals are wet ground (by adding water) to form a slurry and then dried, dry process minerals are dry ground to form a powder like the processes are in use and have their own advantages and in wet process grinding is easier,in dry process there is a saving in fuel costs ...

Get Price